|

Guangzhou Zhongci Magnetic Co., Ltd.

|

Gold Index: 8077

Custom N52 Grade Cylinder Industrial Neodymium Magnets For Loudspeaker RoHS

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

N52 Strong Permanent Magnet for LoudSpeaker with RoHS Compliance Product Description & Specific

N52 Strong Permanent Magnet for LoudSpeaker with RoHS Compliance

Product Description & Specification:

Good Loudspeaker begins from choose high quality magnets. Good quality magnets is in Zhongci!

1. Grades

Range: N35-N52; N35M-N50M;

N35H-N48H, N35SH-N45SH;

N30UH-N40UH, N30EH-N38EH.

Professional suggestions:

- The grade like N48-N52 could meet your requirements on strong power.

- Standard one like N35 or N40 is okay for your normal applications.

- If you have requirement on the working temperature, please note it.

Maximum Working Temperature:

N35-N52, 80°C(176°F)

35M-50M, 100°C(212°F)

35H-48H, 120°C(248°F)

35SH-45SH, 150°C(302°F)

33UH-40UH, 180°C(356°F)

33EH-38EH, 200°C(392°F)

28AH-35AH, 220°C(428°F)

2. Shapes

Others available: Block, Ring, Cylinder, Disc, Customized shape as your design.

3. Size

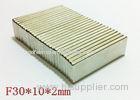

Block / Bar | Length x Width x Thickness |

Disc / Cylinder | Diamter x Thickness |

Ring | External Diamter x Internal Diameter x Thickness |

Irregular | According to customer's size or drawing request. |

You could choose freely according to your plan.

4. Coatings

Others available: Nickel, Zinc, Gold, Silver, Epoxy, Parylene, etc.

Coating and Corrosive Resistance of Sintered NdFeB | ||||||

Surface | Coating | colour | Thickness | Resistance can be | Corrosive Resistance | |

PCT Test | Salt Spray Test | |||||

Nickel | Ni/NiCuNi | Silver | 10-20 | 48h/72h | 72h | excellent |

Zinc | blue zinc/colour zinc | brightblue/shinyblue | 8-20 | 24 | 24 | good |

epoxy | epoxy/NiCu+Epoxy | black/grey | 15-25 | 48 | 96 | excellent |

Tin | NiCuSn | silver | 15-20 | 72 | 72 | superior |

Parylene | Parylene | grey | 15-25 | 96 | 200 | superior |

Teflon | Teflon | grey | 10-20 | 12 | 24 | superior |

Phosphorization | - | grey | 1-2 | - | - | temporary protection |

Passivation | - | grey | 1-2 | - | - | temporary protection |

5. Orientation

Through the direction of thickness or according to your needs.

a. Thickness Magnetized

b. Axially Magnetized

c. Diametrally Magnetized

d. Mult-poles Magnetized

e. Radial Magnetized

f. Customzied Specific Requirements Magnetized

6. Product process flows

7. Applications:

Competitive Advantage:

- Original manufacture

- More than15years magnet manufactured experiences(since 1999)

- Competitive price, stable quality, fast delivery, good service.

Please have the following information avaliable when you contact us.

- The magnet’s Grade.

- Any details on finish of surface.

- Dimensions, tolerances, shapes.

- Application for magnet.

- Quantities.

- Any other specifications & information.

We can manufacture a custom magnet for your application.If you have any question,please do not hesitate to contact me.

FAQ:

1.What’s the payment terms?

- T/T in advance (telegrafic transfer - bank order), for new customer, or small order , or samples order, or shipment by air.

- L/C for larger order.

- Any other payment terms,we can talk over them.

2. Sample fee?Delivery date?Shipment?

- Sample fee: If it is commonly used specifications of the products and our warehouse have inventory, we can provide you with free samples; Customized specifications of the products, we need a certain amount of sample fee to control the cost of material.

- Delivery Date: It's according to the contract,If for any reason there is a delay, we will contact you with an estimate of the revised delivery date.

- Shipment: We always use DHL Courier company.Fed Ex,EMS etc.,we can talk over this.

3. Will magnets lose their power over time?

Do lose a very small fraction of their magnetism over time. But if elect the wrong materials and exceed the max work tempreture,magnet will lose magnetism forever.

4. Why are most neodymium plated or coated?

A: Neodymium magnets are mainly constructed of Neodymium, Iron and Boron. Iron can oxidize very easily when exposed to moisture and will rust over time.

About us:

Zhongci Holding:

Guangzhou ZhongCi Magnetic Co., Ltd(Location: Zengcheng, Guangzhou)

MingJie Magnets Co., Limited(Wuxi, Jiangsu)

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Guangzhou Zhongci Magnetic Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Guangzhou

Province/State: Guangdong

Country/Region: China (Mainland)